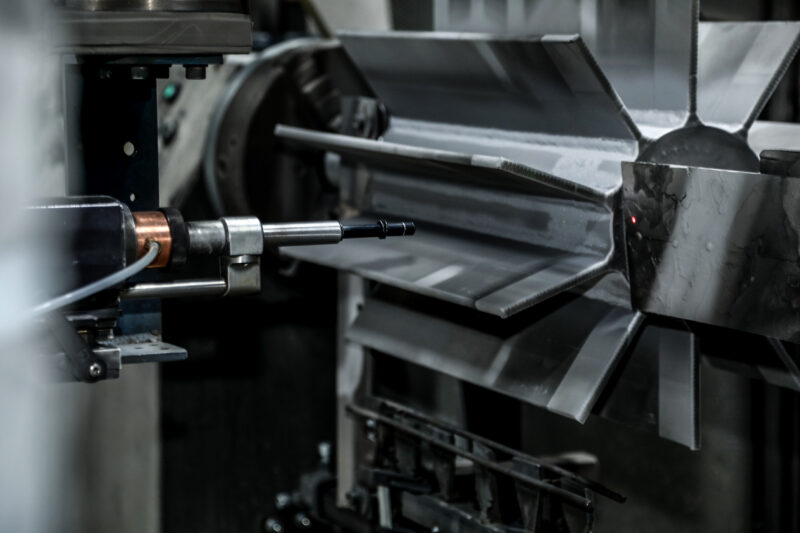

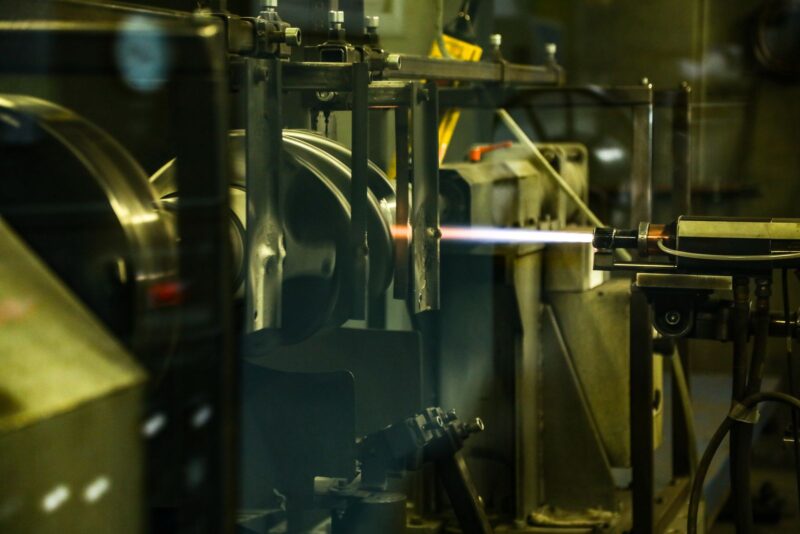

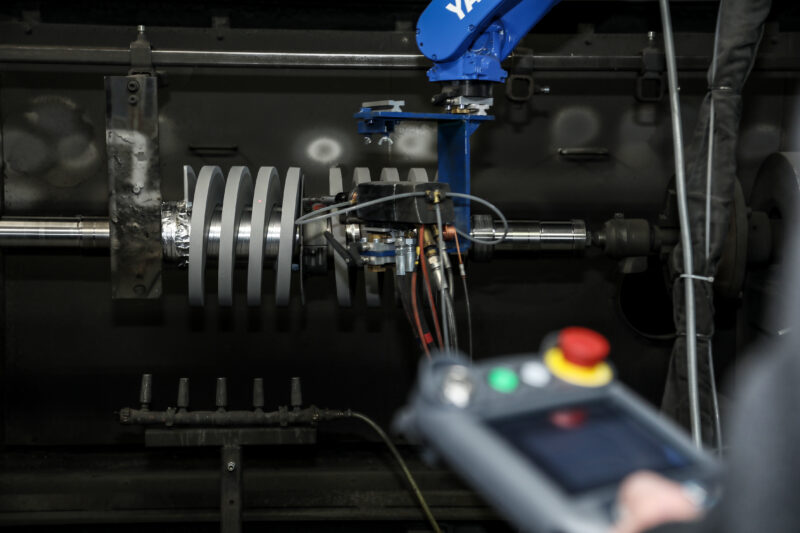

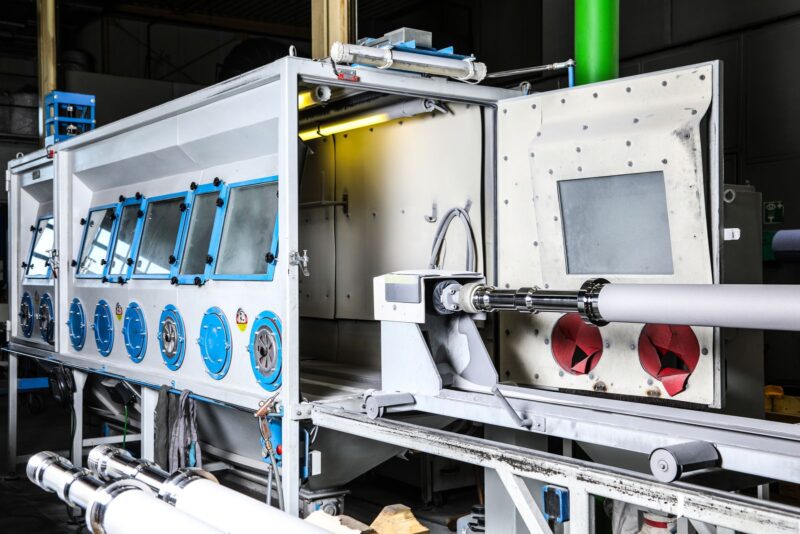

Thermal Spraying

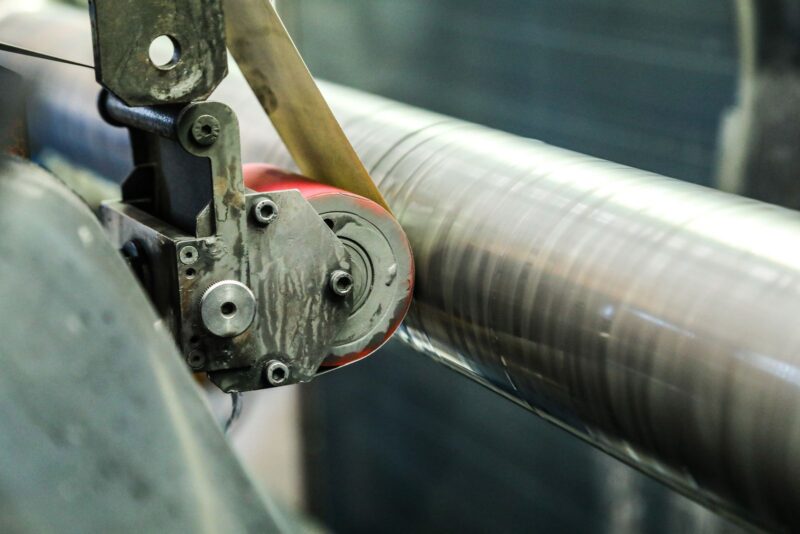

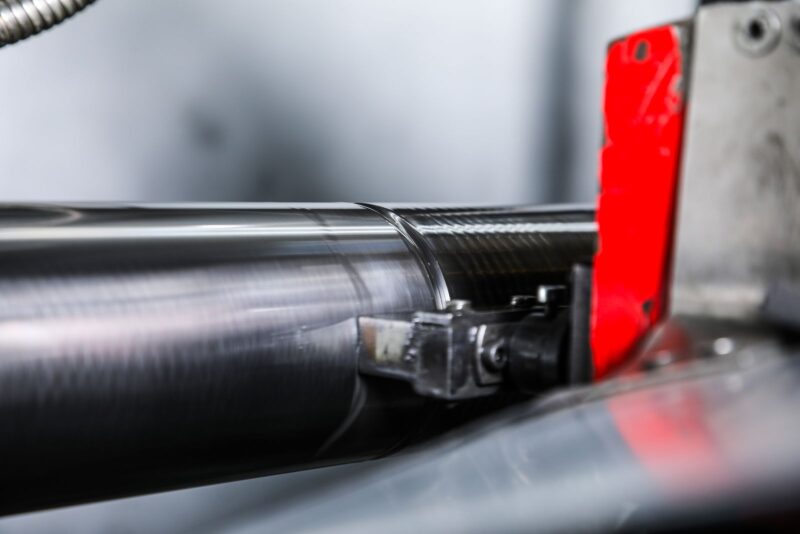

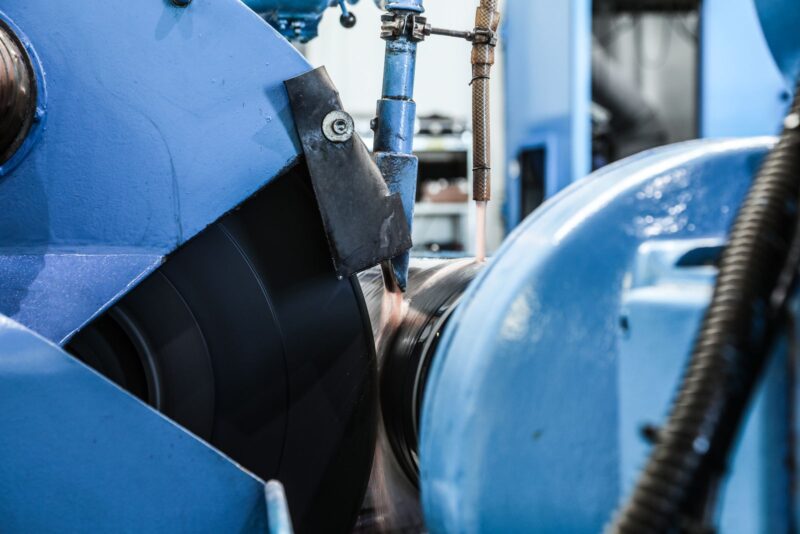

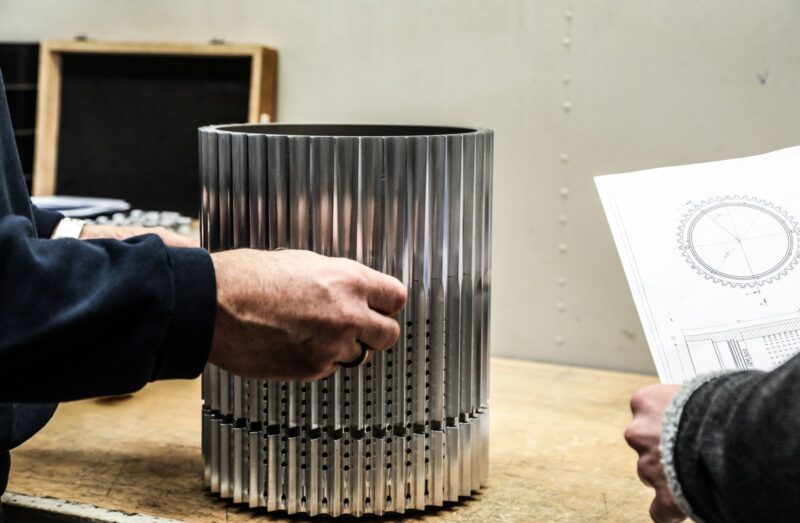

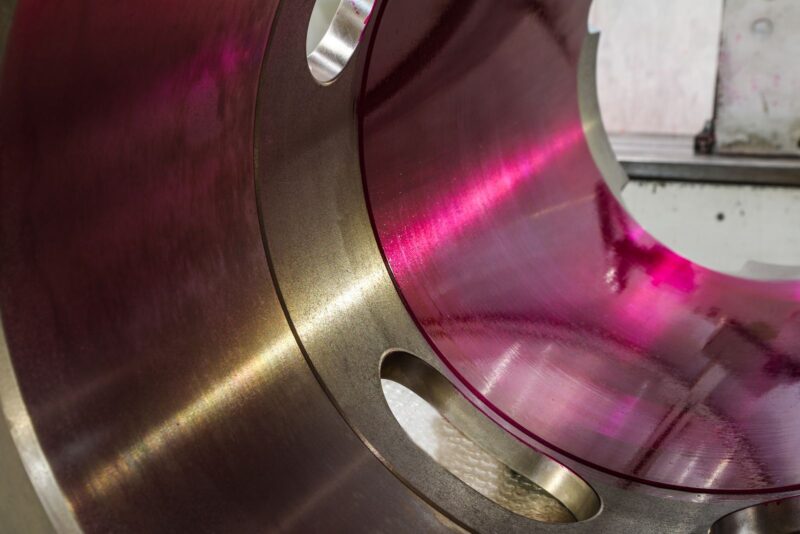

In thermal spraying, a coating material in form of powder or wire is melted or fused and accelerated onto the component surface. Coating materials used in thermal spraying are metals, alloys, hard metals, cermets or ceramics. The wide range of coating materials and properties makes thermal spraying superior to many other coating processes.

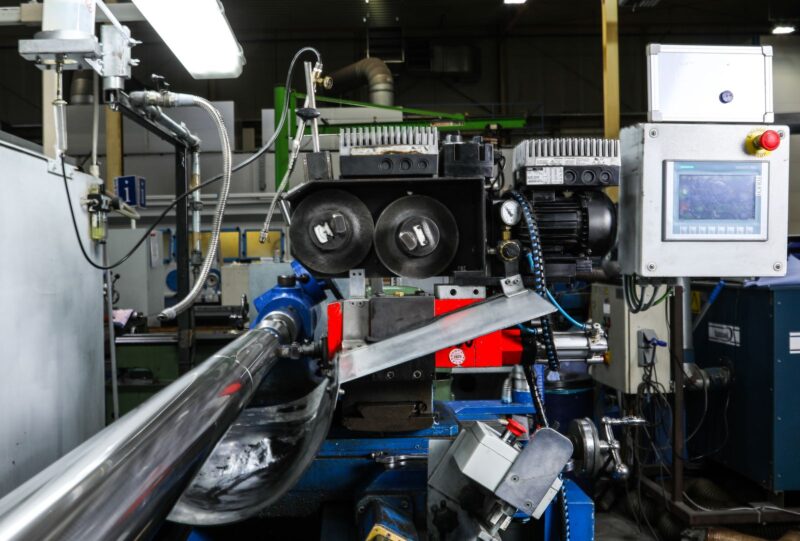

Depending on the coating material and application we use different thermal spray processes:

- High velocity oxy-fuel spraying (HVOF)

- Atmospheric plasma spraying (APS)

- Powder and wire flame spraying

- Wire arc spraying

The coatings properties, such as wear and corrosion resistance, hardness and adhesive strength, are determined by the coating material and also the spray process. The typical coating thickness varies from less than one tenth of millimeter to several millimeter, depending on the type of coating and the application.

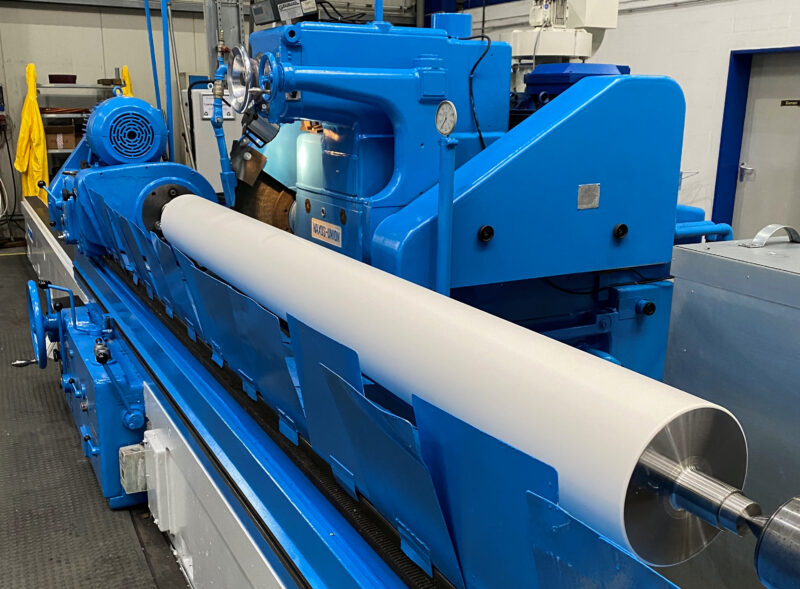

We coat components with a diameter up to 3.300 mm, a length up to 13.500 mm and a weight of 20 tons. Coating of inner diameters is possible from a diameter of 80 mm.